Kanban is a key element of just-in-time production systems in manufacturing. Kanban is used to optimise the supply chain and avoid inventory build-up. Historically the model is based on supermarket operations, where the quantities for items on shelves is based on estimated demand and what customers are expected to purchase. Replenishment is triggered based on empty spaces and a request is issued to refill the items consumed.

Kanban systems are demand driven, based on the principle of a chain of customers. Each process issues a request to suppliers when it consumes supplies. Production is based on the incoming requests and no item shall be made or transported without a request. All items have the request attached to it, the Kanban card. For items supplied in re-usable containers, the Kanban card is usually attached to the container.

Companies reduced errors from manual data entry with the introduction of Barcodes. Barcodes allowed to improve the efficiency and accuracy of capturing information from the Kanban card in ERP systems.

RFID based Kanban further automates the process by collecting Information about supply levels across the supply chain to the point of consumption on manufacturing lines.

Digital Transformation of Kanban

Kanban has been a huge success and is an integral part of today’s lean and just-in-time manufacturing. Cards and containers are collected from the production lines and supply is initiated from the supermarket. RFID based Kanban shelves enable production and supply chain managers to have full visibility into stock levels and requests for replenishment can be automated when containers are moved to the return shelf.

Benefits of RFID enabled Kanban

RFID provides companies with the ability to automatically capture information without the need for line of sight. Enabling Kanban shelves and containers with RFID data can be captured from the manufacturing lines in real-time. Visibility into stock levels is improved, supply can be optimised, and demand automatically captured. Errors from lost or damaged Kanban cards can be minimised.

Vertical Integration

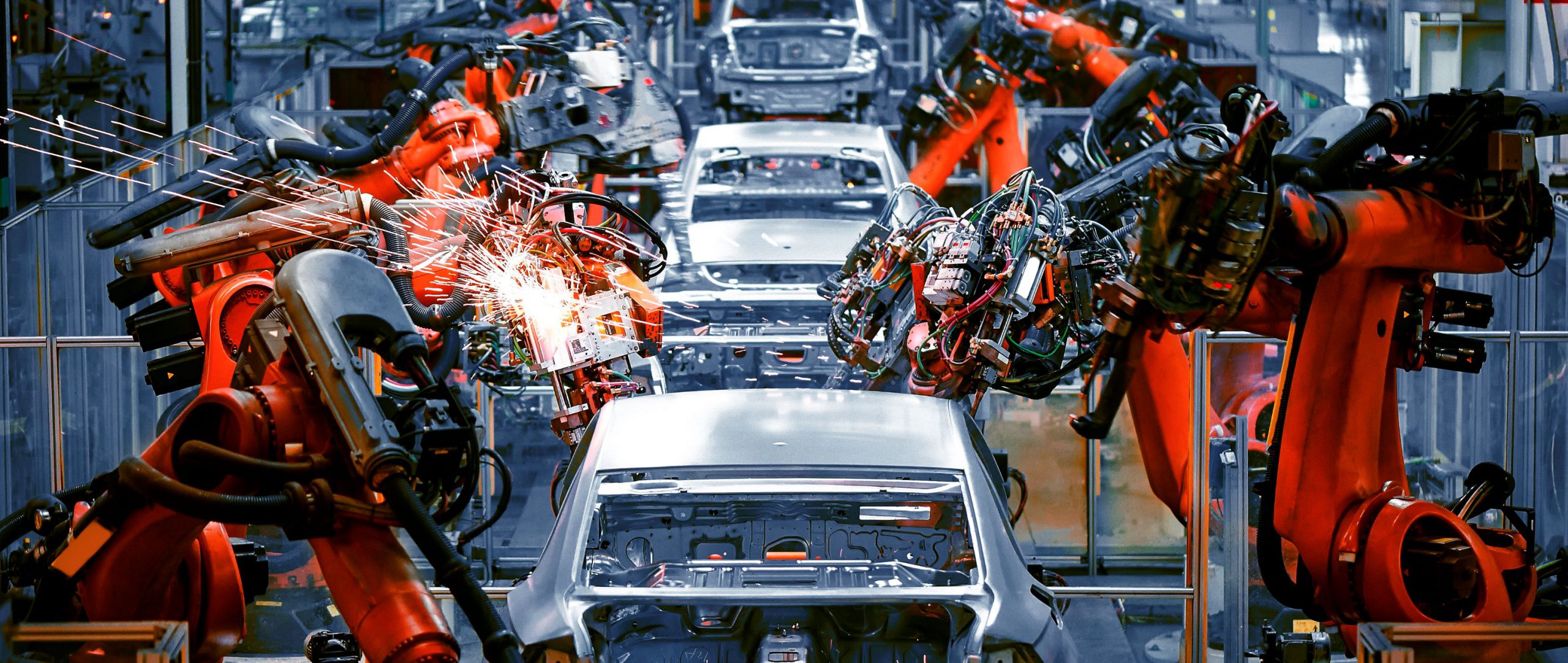

In automotive up to 75% of the value creation is coming from OEMs and suppliers. Close cooperation across integrated supply chain systems is an integral part of efficient operations. (see VDA) Accurate data in real-time provides companies with complete end-to-end visibility of complex processes and transactions.

What is Kanban

Kanban (看板) (signboard or billboard in Japanese) is a scheduling system for lean manufacturing and just-in-time manufacturing (JIT).